Page 1 of 1

Brand new toy!

Posted: Sat Jan 04, 2014 10:09 pm

by audiophyle_247

I am the proud owner of a ShapeOko2 CNC Mill, or will be as soon as I finish building it. lol

This is what came right out of the box.

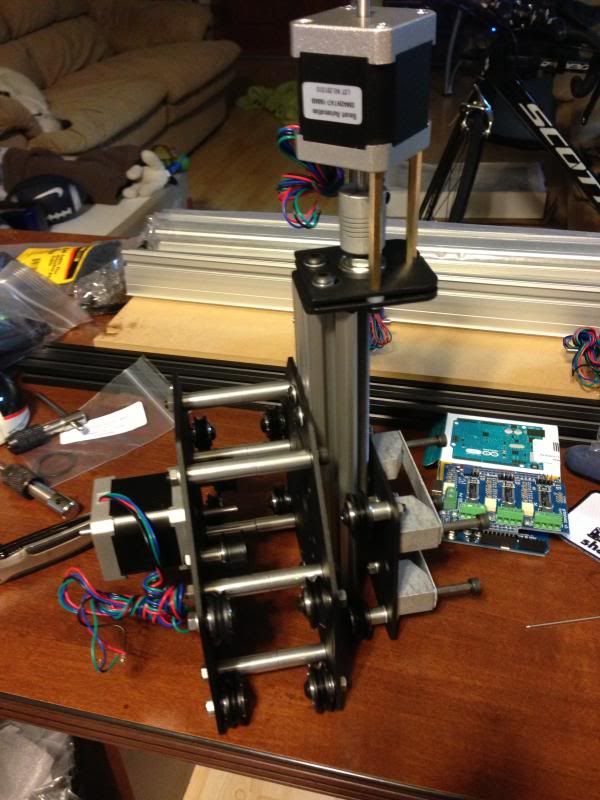

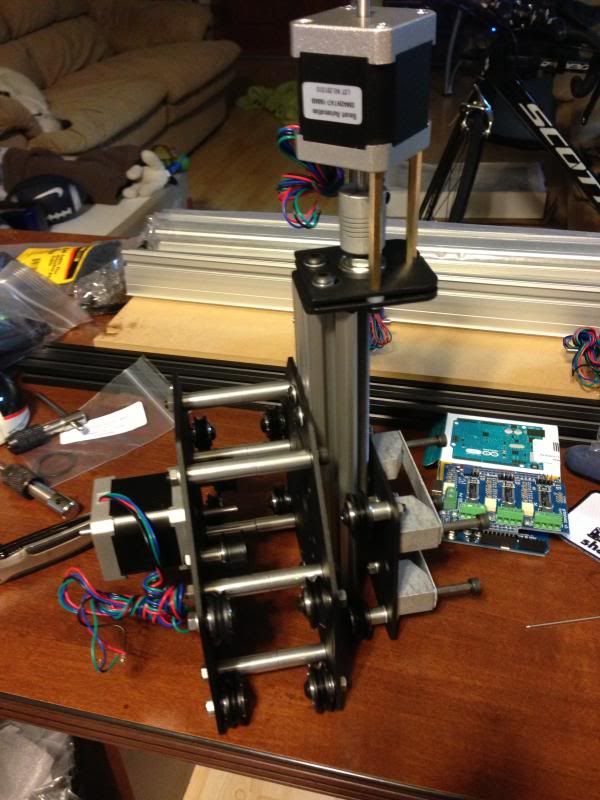

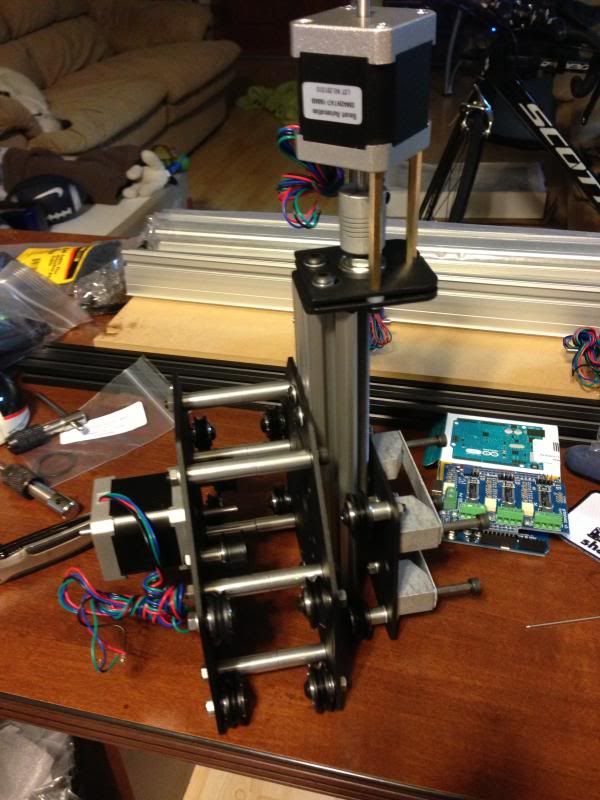

Assembled the Z axis with X axis mount.

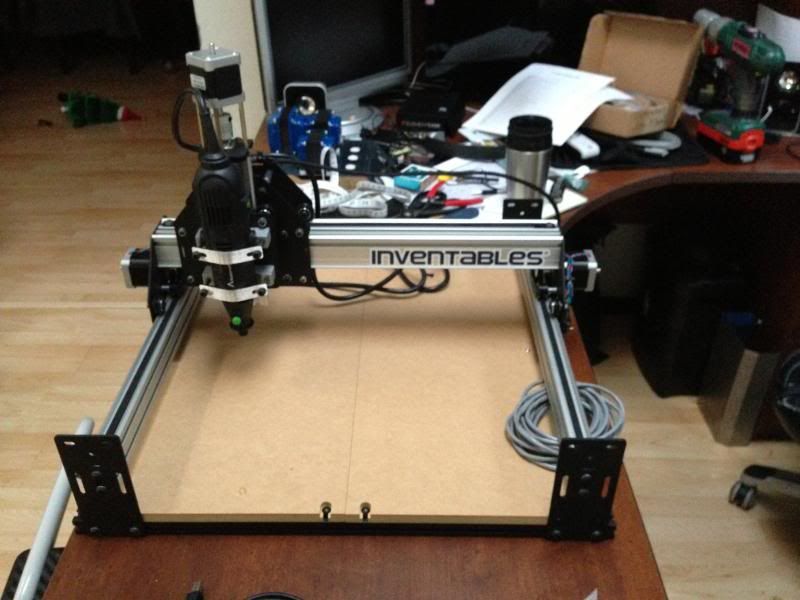

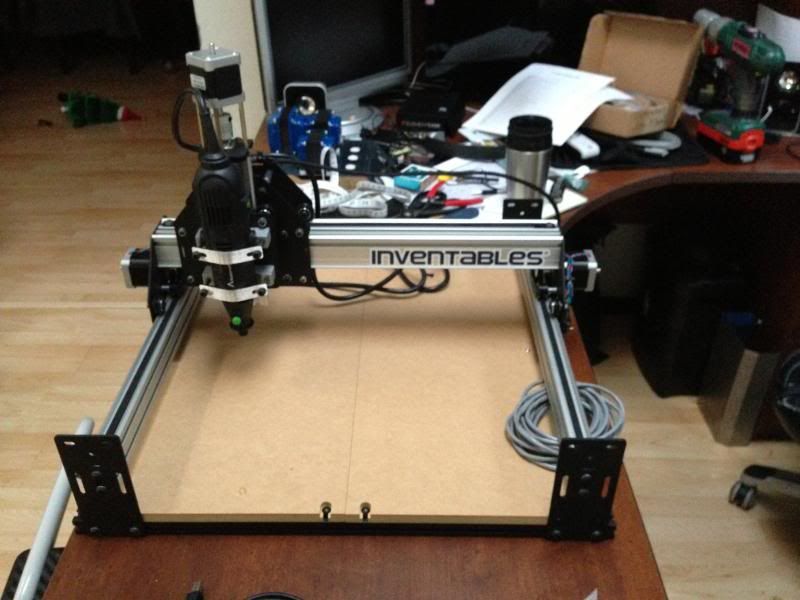

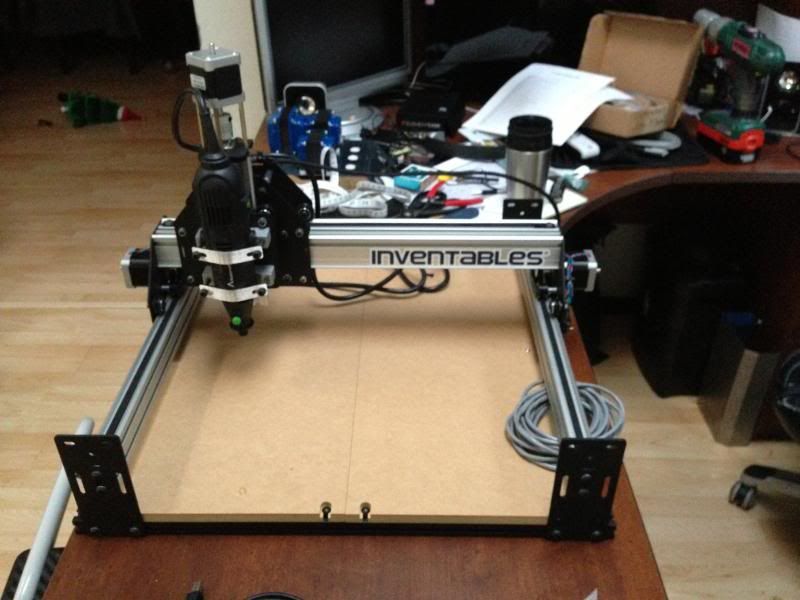

And with all of the mechanical goodies put together.

Just need to finish wiring it up & fab a housing for the Arduino & driver board.

Ive had so much fun putting this thing together that I just had to share.

Re: Brand new toy!

Posted: Sat Jan 04, 2014 10:22 pm

by ttocs

too cool. Is this just for fun or a small biz? And how much?

Re: Brand new toy!

Posted: Sat Jan 04, 2014 10:41 pm

by audiophyle_247

Primarily just for fun because I have wanted one for a long time, but will surely collect some extra play money from projects here & there. The circuit boards were what brought those bass cube remotes to a halt, they cost too much to have fabricated and making them by hand took forever. Now I can engrave my own, for remotes and the many other projects I have had in mind.

I bought the complete kit from Inventibles.com for $700 or so. I had planned on eventually building one myself, but after putting this "kit" together doing one completely on my own would have been a nightmare & easily cost more. This kit is impressive & very well thought out, and my favorite part is I can scale it up in size easily & is very affordable.

Re: Brand new toy!

Posted: Sun Jan 05, 2014 7:20 am

by ajaye

dude that's kind of insane in the best way possible.

on a related note, when people are talking about "3d printing" that I keep hearing about, is it basically something like this? or a whole different type of machine/process?

Re: Brand new toy!

Posted: Sun Jan 05, 2014 10:55 am

by audiophyle_247

3d printing is a lot more like an actual printing process. The machine lays down thin layer upon layer of materials to slowly build something 3d. It is an additive process.

Milling is a subtractive process, where a block of material is used & the mill removes all of the excess material to leave the desired shape behind.

Milling has been around for a long time, and 3d printing is slowly making its way into manufacturing processes. It's also very expensive if you want to print in anything other than plastic, sand, or paper.

Re: Brand new toy!

Posted: Mon Jan 06, 2014 7:42 pm

by dbjury

Cool.... Very!

Sent from my slutty assistant...

Re: Brand new toy!

Posted: Mon Jan 06, 2014 8:16 pm

by ttocs

$700 is all??! I would have thought it was a lot more then that. I might have a small job for you when I get time to make my amp rack. I want to make it from aluminum and weld it together....

Re: Brand new toy!

Posted: Mon Jan 06, 2014 9:39 pm

by audiophyle_247

Wife thought I was crazy, but that was my reaction too. lol

For the price it is awesome, and the cutting area is a little on the small side (12"x12"x3") but I can expand that to almost 3'x3' for just over $100 if I ever need to. (can go larger, but that gets very expensive)

I primarily wanted it for the precision & to mill small parts anyway, so it should be perfect.

Re: Brand new toy!

Posted: Mon Jan 06, 2014 10:18 pm

by ttocs

it amazes me the technology that people can buy now. I have another buddy that has a small laser version that he uses for custom making balsa piece for his rc heli's that amazes the hell outta me.

Re: Brand new toy!

Posted: Sat Mar 08, 2014 12:12 pm

by audiophyle_247

Upgraded the spindle from the worthless 200w generic dremel to a 1.25hp Makita, all the difference in the world! Following vids are cutting through acrylic in 1/8" bites per pass with a very slow feed with the Makita turned down to its slowest setting. Right now the feed/speed settings are not optimal, it is spinning too fast & feeding too slow, so I will most likely be cranking up the feed rates & turning up the spindle speed just a hair. The power this thing has is awesome!

The cuts are a test pattern to verify accuracy & square of the machine. The cut accuracy was only off by 0.01" and was as close to perfectly square as my calipers could measure.

The belt setup is basic & needs a good tension system, which I am trying to design & fabricate now.

This will help the accuracy further & allow faster feeding speeds without loss of accuracy.

I am also working on a dust collection setup to keep the work area clear.

Re: Brand new toy!

Posted: Sat Mar 08, 2014 7:05 pm

by LowandLoud

Man.... You are the envy of the Phorum right now, lol. This is sweet. I too am surprised how affordable it is. Too cool.

LL

Re: Brand new toy!

Posted: Sat Mar 08, 2014 10:29 pm

by Bomber Z

Awesome!!!!! That is so cool...

Re: Brand new toy!

Posted: Mon Mar 10, 2014 7:58 am

by trickyricky

That sure do look like a sweet toy to have. Was the Makita an optional upgrade or was it your add on? I ask because that mounting hardware on it seems like it was custom made or made exactly for that model.

Re: Brand new toy!

Posted: Mon Mar 10, 2014 7:33 pm

by audiophyle_247

The best part of the ShapeOko community is everyone works toward perfecting it & there are countless iterations shared on their forum. The Makita was an upgrade I chose because I found it locally & the price was right. The mount was snagged off eBay which was the exact sizeneeded for the Makita & it just happened to fit the mill perfectly too. (couldnt have been happier when I discovered that btw)

The cutting area is still pretty small at just over a sqft, but it can be expanded pretty easily & I plan to eventually.

Ive already cranked out several speaker rings for friends & fab'd up a replacement part for my shopvac out of ABS plastic.

Waiting on engraving bits in the mail & I hope to be engraving circuit boards pretty soon, so I can perfect my basscube remotes. (& mill the mounting plates too)

Re: Brand new toy!

Posted: Mon Mar 10, 2014 8:03 pm

by trickyricky

You think you could do a simple end plates (2" x 12") out of aluminum or steel that is 1/8" thick. I need a couple for two amps that are in horrible shape and would like to customize the end plates.

Re: Brand new toy!

Posted: Mon Mar 10, 2014 8:14 pm

by audiophyle_247

This setup isnt strong enough to mill steel, but it can do aluminum.

I however have no experience milling aluminum, yet. I dont see why not though, do you have a sketch or picture of what you are looking for?