Page 1 of 1

CNC pinewood derby car

Posted: Mon Jan 18, 2010 10:48 am

by Jacampb2

My nephew asked me to help him make a "Awana Grand Prix" car, these are pretty much the same as the BS pinewood derby, but it is a church run group. So, we set out to make one on the CNC mill.

Before anyone gives me crap about doing this for him, the only thing I am doing is setting up and running the machines. He's only 12, and I am trying to teach him about the machines and the software. I helped him design the model in sketchup, we exported it to 3ds format and imported it into artcam. I setup the tool paths, and he's doing all the finish sanding. The car is also going to have working LED headlights, and so he's going to learn some very basic electronics stuff as well.

I have no idea how this thing will preform, we were going for more of a really cool look.

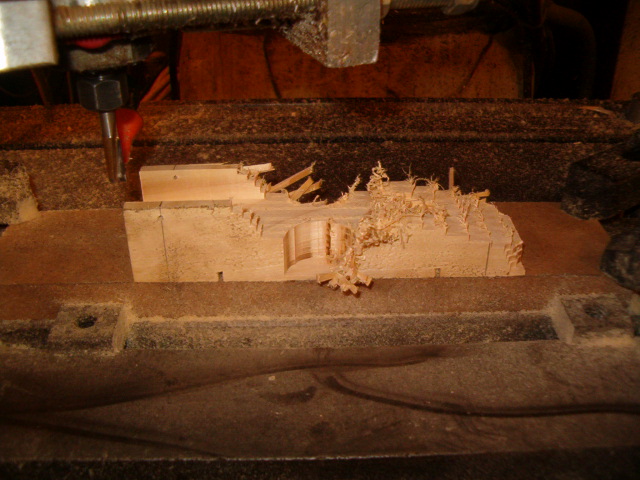

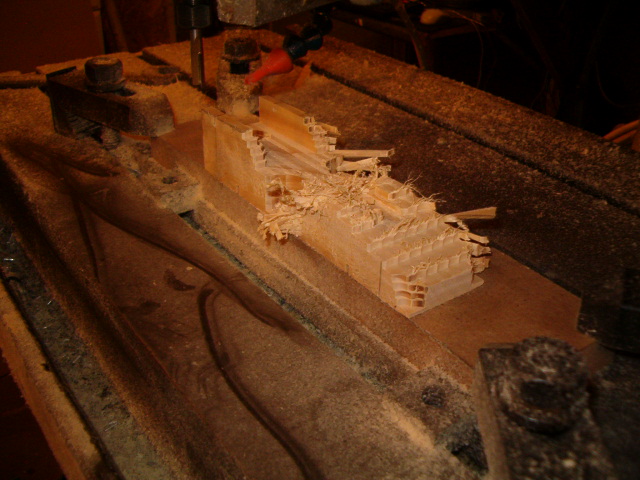

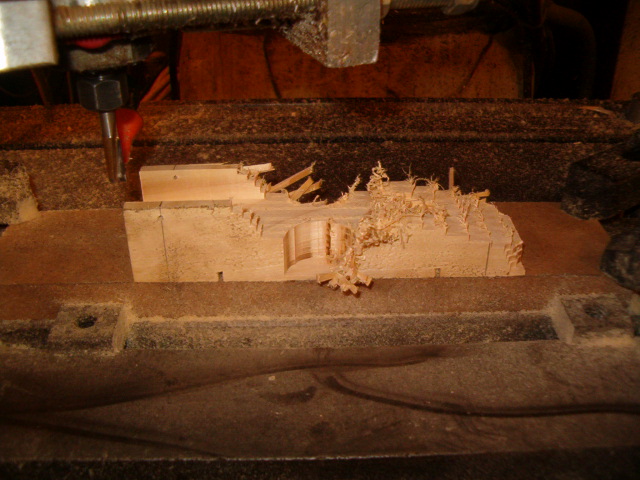

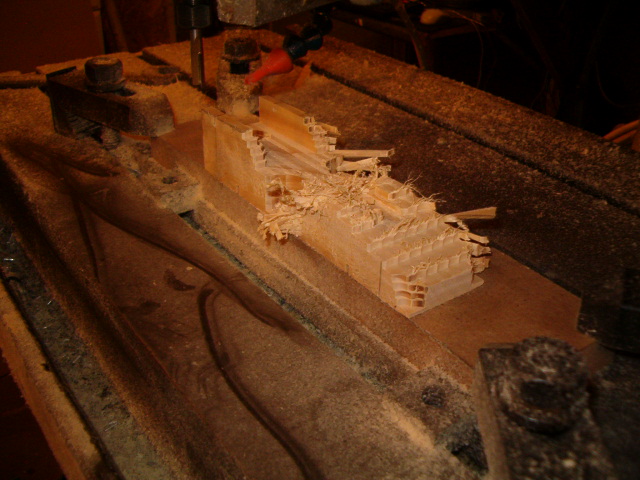

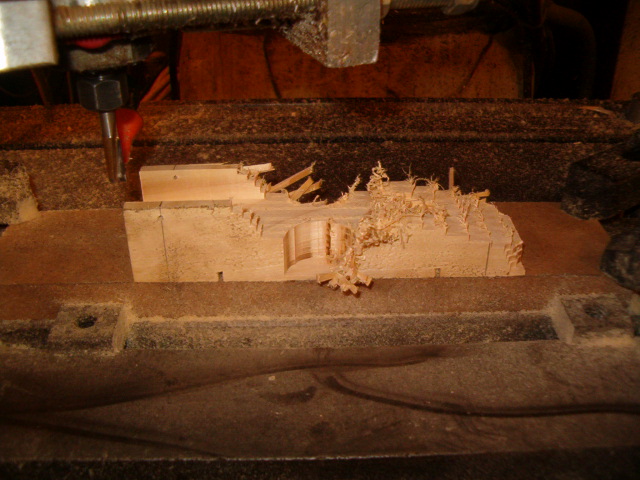

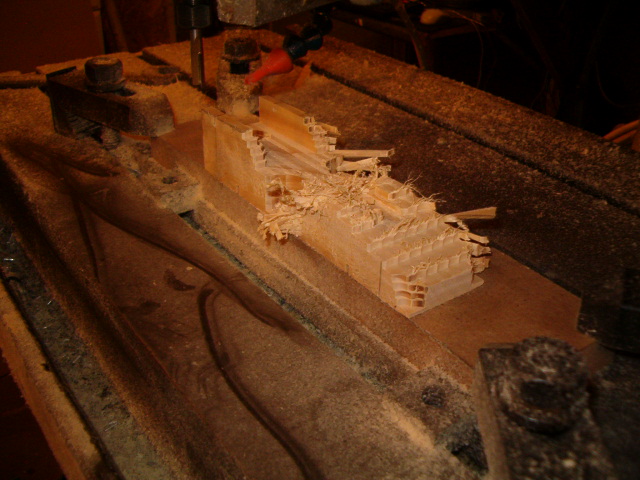

Here are the pics so far:

Model roughed out

3d finish passes, and a lot of hand sanding

Later,

Jason

Posted: Mon Jan 18, 2010 10:50 am

by Bfowler

thats the COOLEST. keep the pics coming!

Posted: Mon Jan 18, 2010 2:11 pm

by ttocs

I use to love the pinewood derbys in the scouts.

Posted: Tue Jan 19, 2010 11:58 am

by Jacampb2

Here is where we are today. Electrics are in for the headlights. Twin 3mm white leds, a little push button switch and a 3v lithium coin cell. Machined a little cowl today to cover up the battery and switch, you have to remove the cowl to turn the lights on and off though...

The wiring channel is going to get filled with body filler here in a few minutes, and we'll fill the chips and holes that were from mounting it and machining it. We're at 3oz right now, limit of 5oz, so we have room to go with weight.

Here are some pics:

Later,

Jason

Posted: Tue Jan 19, 2010 12:05 pm

by fuzzysnuggleduck

This is what we used to do in junior high school:

http://en.wikipedia.org/wiki/CO2_dragster

I had a bad ass car that rocked but we launched it one day without having the guide line as taught as necessary and it veered off straight into the lockers (raced in the school hallway) and blew up!

I didn't have any cool shit like lights or a CNC to cut it out though, that's pretty sweet. We did use a lathe for initial rough cutting, though... and had to draft up the design using drafting tools and skills.

it4em

Posted: Tue Jan 19, 2010 12:06 pm

by kg1961

very cool

wish i had you as a dad when i did mine as a kid say 25 years ago

Posted: Tue Jan 19, 2010 3:58 pm

by ttocs

never heard of the co2 racer, that had to be a pretty coole explosion in the hall of yer school!

Posted: Wed Jan 20, 2010 4:03 pm

by Jacampb2

Here are some progress pics from today. He changed his mind on the headlights, we went from white to orange (they show up yellow in the camera) today, luckily I hadn't glued the white ones in yet.

Anyhow, lights are permanent now, we've filled the channel with bondo. We made a little wing for it, and glued it on. Also changed the design for the cowl a little bit to allow access to the switch underneath w/o having to remove it. Hopefully, tomorrow after he finishes sanding it, we'll will be ready for paint.

Here's the pics:

Later,

Jason

Posted: Wed Jan 20, 2010 5:05 pm

by mhyde71

very cool jason, very cool

need the rims powder coated, maybe franked - (per gratis)???? LOL JK well kinda anyways

matt

Posted: Thu Jan 21, 2010 2:22 pm

by OldSchoolFool

dunno, looks kind of "tuner" to me, hahaha

JUST KIDDING.

That is F*cking awesome.

THE POWER OF CAD + CNC!!!!!!!!

Posted: Thu Jan 21, 2010 6:05 pm

by Jacampb2

Well, it is almost done, and I am out of time to help, I go back to work tomorrow night.

He sanded entire car progressively smoother from 60grit to 320grit. We shot it with rattle can primer, he sanded again, we shot two more coats of rattle can metallic paint, and am calling it done. We still need to add two ounces, still hovering right around 3.1oz. Maybe my digital scale sucks...

Anyhow, here is the end result:

Later,

Jason

Posted: Thu Jan 21, 2010 6:42 pm

by fordtough1

That's cool as hell man. Makes my pinewood Countach look like shit.

Posted: Thu Jan 21, 2010 9:34 pm

by ttocs

when you add the weight, try to put it as far back as possible as it will stay on the ramp for just a split second longer then if it was up front.

Posted: Fri Jan 22, 2010 1:11 pm

by Jacampb2

Posted: Fri Jan 22, 2010 1:24 pm

by stipud

Wow talk about overkill!!!

You sure know how to make a mountain out of a molehill don'tcha... not that the results aren't impressive!

Posted: Fri Jan 22, 2010 1:25 pm

by ttocs

graphite powder was the big secret when I did it also. Makes the wheels gluide super smooth but I imagine by now they have bearing kits for them.

Posted: Fri Jan 22, 2010 1:33 pm

by Jacampb2

Bearings are against the rules, might not help anyhow in this sort of application. Powdered graphite is still what they recommend, I bought a can of graphite dry film lube at fastenall though, the dry film lube deposits the graphite in a layer that bonds to the underlying metal, kind of like paint, so it stays in place better than powder.

I actually wanted Teflon dry film lube, but no body around here stocks it, and it is just to late to order a can. The dry film teflon lube have a coefficient of friction of <.01. IIRC, that is about ten times better than graphite...

The races are next Wednesday, hopefully he will get some test time on their track, but it did well on the ramp I built in my shop

Later,

Jason

item

Posted: Fri Jan 22, 2010 1:41 pm

by kg1961

very very cool

Posted: Sat Jan 23, 2010 12:03 am

by ttocs

I was happy to get 3rd my last year there. I have often thought it would be fun to do, maybe I will borrow a friends kid next year and take the easy way out...

Posted: Sat Jan 23, 2010 1:16 am

by bretti_kivi

nice job!

Posted: Sun Jan 24, 2010 8:35 pm

by rlockwood

the key to graphite is to apply it, and then not touch the thing, as its effects wear nearly immediately, IIRC. My boss (and his son) cnc'd a cool one awhile back, but had much better results the next year when they manually made it.. heheh.

Posted: Thu Jan 28, 2010 7:13 am

by Jacampb2

Well, the race is over, in his division he got 1st place for design and second in speed. He's pretty happy, I'm glad he got some trophies. They are moving to Tennessee in about 3 months for at least 2 years, so I won't see them much after this.

Later,

Jason

Posted: Thu Jan 28, 2010 2:16 pm

by andy600rr

Congrats.

Cool as hell.

Posted: Tue Feb 02, 2010 11:10 am

by Pillow

Nice job!!!

My son and I did the Pinewood event last weekend... Some of those cars were very well done and super fast.

It was our first year, now we know what to do

... We will start the project much sooner to get all the stuff really minty. And order the Teflon!