It works. Really, really well. Very surprised.

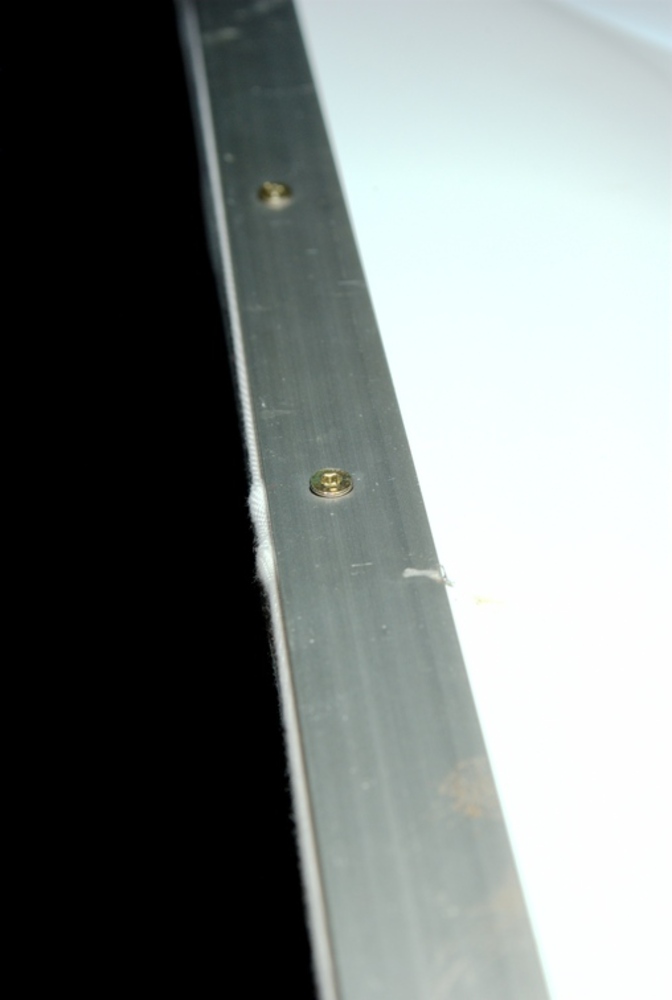

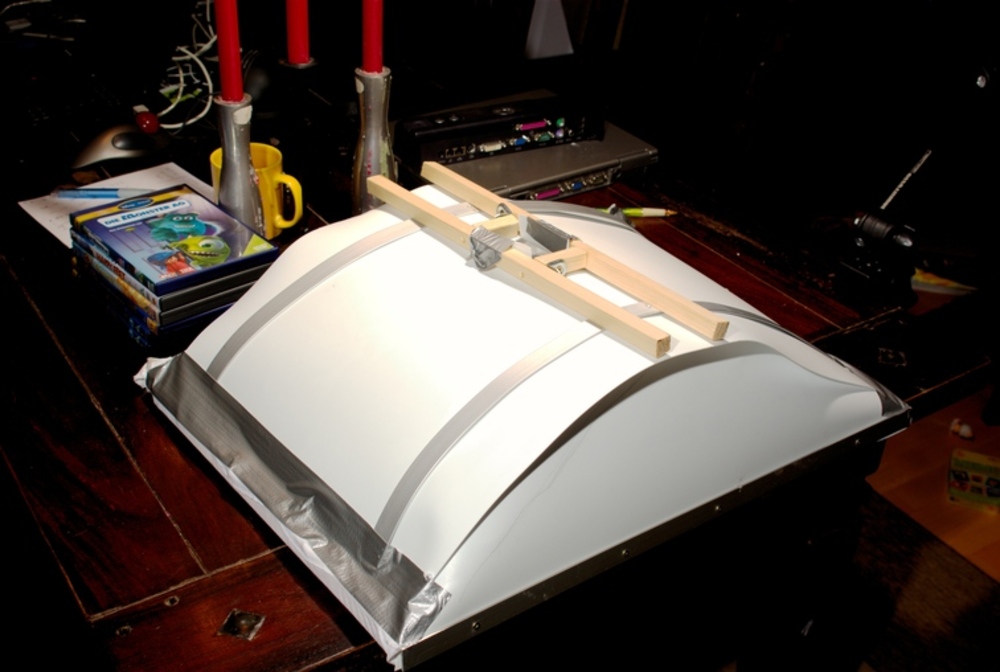

Following some ideas from around the web; 2 600mm long alu tubes, bent for around 45 degree angle top to bottom. 2 flats duct taped in place. Thin plastic (MAPAL) in the centre and on the sides, all taped in place.

Alu foil glued into place as a reflector, a cut-up old t-shirt taped in place over the top. Ta-Daa!

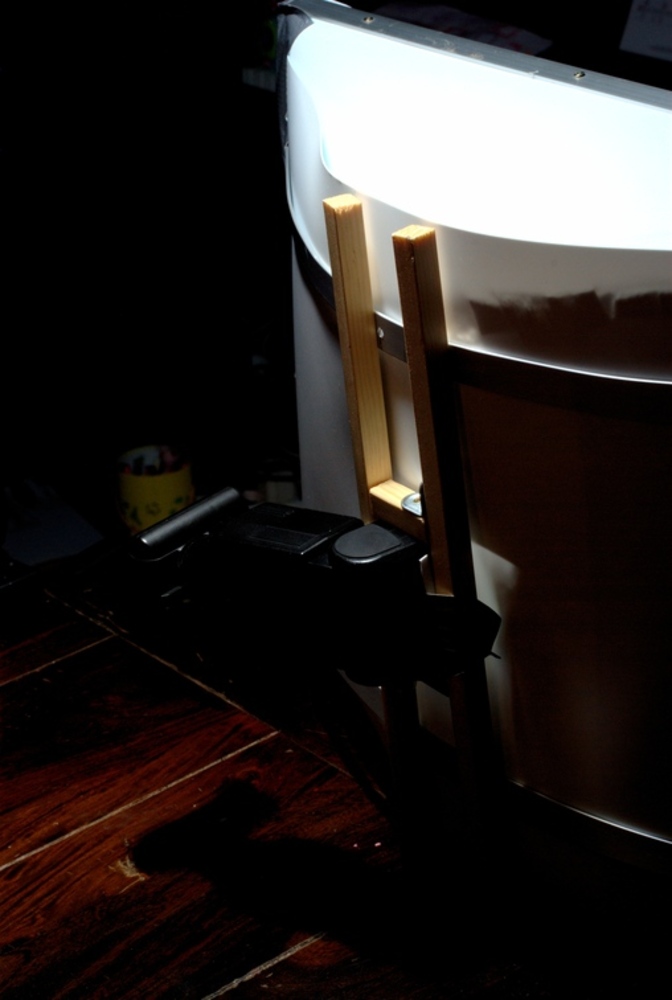

The flash is held in place with the flaps from its hole and some feathering of the edges. Flash on full power is really cool, around 1/8 is enough for macro work at 1/100 & f16.

Very impressed with the results, now all I have to do is make it look slightly less ghetto before I use it in anger at the weekend.

Images:

testing with an ancient Picnic Camel...

Bounced from the ceiling:

Bounced close to the ceiling:

Direct flash, set to 17mm

Softboxed

A test shot or two, note the shadows. The A2 pic has another flash bottom right, firing through the sheet @ 1/32 power (so minimal but still there).

Quick shadow test on the wall. Not quite fair as the 'box was on an arm an so around 70cm above the table, but even so. Both flashes set to 28mm, full power. My position isn't identical, but it's in the corner next to the balcony so it's very similar. Both are 0.5s f8.

The box itself: the curve is around 600mm long and 300mm wide. 150mm deep, the front is 560mm long.

Bret