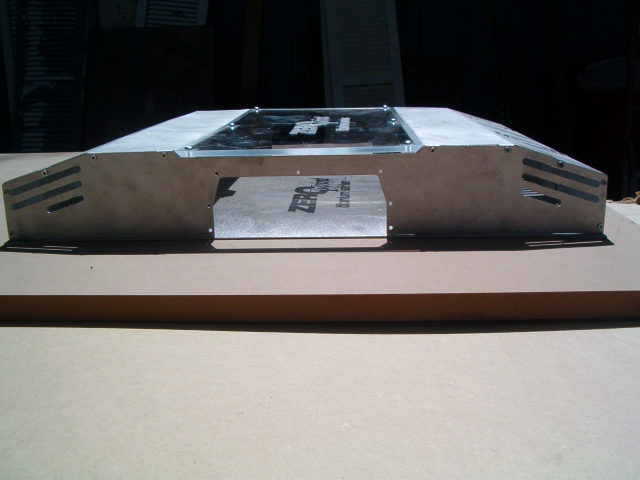

I got to buy ZPA amps now

Any way to flip the boards around and make cut outs for the terminals?

Walker, I had thought about dyeing it. I know that rit works for a startling variety of things, but didn't know if ABS was porous enough to take the dye. Do you dye in a hot solution, or just room temp?walker01s10 wrote:On the abs plastic just buy some rit dye and dye them black. I dye plastic all the time just do all the machine work first. And as long as you don't scratch the abs to deep it will stay black forever.

Jacampb2 wrote:Thanks again guys! I am back to work again, so progress will slow down again...

Walker, I had thought about dyeing it. I know that rit works for a startling variety of things, but didn't know if ABS was porous enough to take the dye. Do you dye in a hot solution, or just room temp?walker01s10 wrote:On the abs plastic just buy some rit dye and dye them black. I dye plastic all the time just do all the machine work first. And as long as you don't scratch the abs to deep it will stay black forever.

Thanks,

Jason

Jacampb2 wrote:Thanks again guys! I am back to work again, so progress will slow down again...

Walker, I had thought about dyeing it. I know that rit works for a startling variety of things, but didn't know if ABS was porous enough to take the dye. Do you dye in a hot solution, or just room temp?walker01s10 wrote:On the abs plastic just buy some rit dye and dye them black. I dye plastic all the time just do all the machine work first. And as long as you don't scratch the abs to deep it will stay black forever.

Thanks,

Jason