M50 and M44 - advice

I think something happened to www.soundbuggy.com, because the link is not working for me either.

Check it again when you get a chance. I have a tutorial there with images showing how to remove the caps and replace them, along with some other useful information.

Check it again when you get a chance. I have a tutorial there with images showing how to remove the caps and replace them, along with some other useful information.

C31 and C32 are the ones that like to heat up and cook because of heat from those big drop resistors. I elevate the caps also as the longer leads help stave off the heat absorption the the gold traces bring to them. Also the zener diodes right beside them get Hella hot also. please at minimum resolder these as the solder on both these and the resistors breaks down from the heat at the contact points of the circuit board....C

Man this is getting confusing...

Please bare with me I really do appreciate it.

Looking at the M50 picutre...

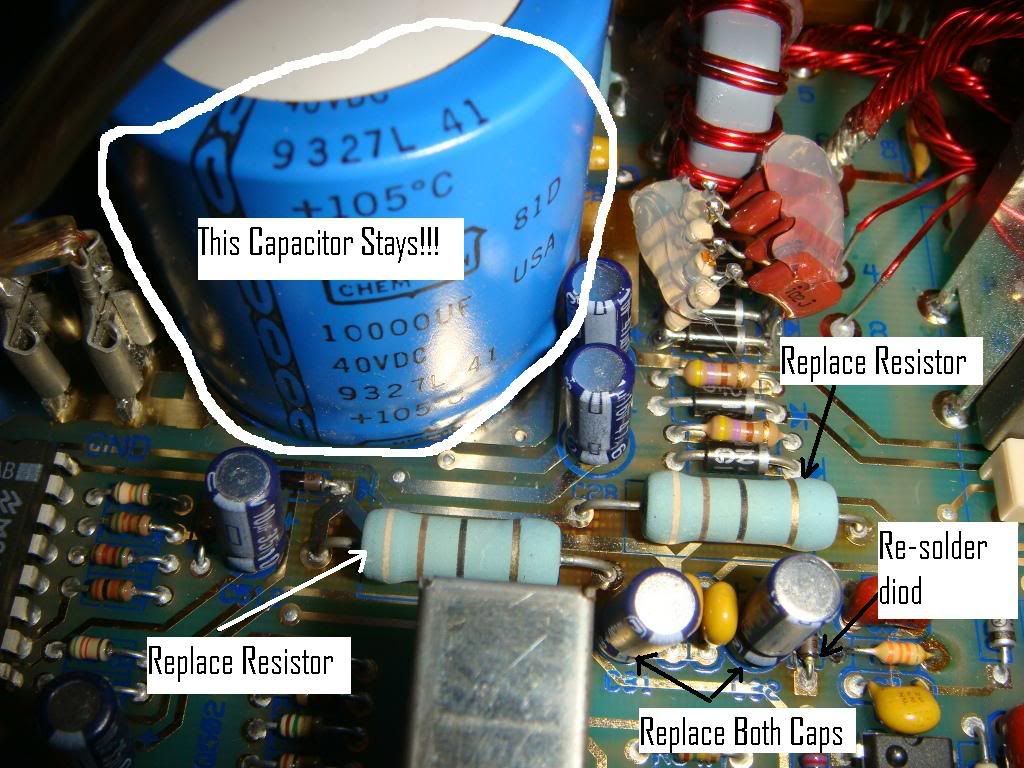

The only resistor being replaced is the one with the Orange/Orange/Red/Gold stripes. The 4 resistors in the upper right of the picture remain (Red/Black/Gold).

The small capacitors being replaced will be the two immediately below the big resistor being replaced. Additionally, the two diods on either side of the small capacitors will be re-soldered. The two yellow things in between the small caps to be replaced will be untouched.

Is that correct? Once I get the M50 straightened out I'll go on to the M44.

Please bare with me I really do appreciate it.

Looking at the M50 picutre...

The only resistor being replaced is the one with the Orange/Orange/Red/Gold stripes. The 4 resistors in the upper right of the picture remain (Red/Black/Gold).

The small capacitors being replaced will be the two immediately below the big resistor being replaced. Additionally, the two diods on either side of the small capacitors will be re-soldered. The two yellow things in between the small caps to be replaced will be untouched.

Is that correct? Once I get the M50 straightened out I'll go on to the M44.

Last edited by denisl on Thu Jan 03, 2008 12:31 pm, edited 1 time in total.

The soundbuggy web site looks to be working again.

Here is that link…

http://www.soundbuggy.com/Eric/Car%20Au ... index.html

You may also find value with this link, which gives some more ideas for tweaking your amp…

http://www.soundbuggy.com/forum/viewtop ... 78&start=0

Here is that link…

http://www.soundbuggy.com/Eric/Car%20Au ... index.html

You may also find value with this link, which gives some more ideas for tweaking your amp…

http://www.soundbuggy.com/forum/viewtop ... 78&start=0

M-44 looks good I would run with your last post. the big resistors will have a bad oxide build up so replacement will most likely be easier as per Doc's call out... They appear to in good shape, but if you try to resolder them they will not take solder on the leads due to oxide build up. options are replace and elevate or remove and scotch brite and reinstall with clean wire surface so they will take solder. I like Doc's idea off replacement and elevate.

M-50

R33 and R34 are the hot resistors that MAY or may not need servicing. I like to reflow the solder at minimum, but these get oxided from heat so bad that the wire leads will not take solder.

So you might have to remove these and either replace them or scotch brite the lead wires to get the oxide coating off so it will take solder.

CR-12 and CR-13 are the zeners that get hot and MAY or May not need reflowing the solder. Here again its what you see when you get there. yours look pretty OK by by the pic you listed.

C-31 and C-32 are the ones that usually get baked. In your pic they appear to be good but it only cost like $1.00 to replace these and get that feel good feeling that you did the right thing. Please upgrade to 105 C rated devices if you do replace these. please elevate by 1/4 to 1/3 inch away from the board to aid in heat dispersion >

C-33 and C-34 are ceramic type caps, these rarely if ever fail. When they do you will know as they will most likely short, and burn up beyond recognition taking the traces and baord are with them as they leave for the nether regions.

on your M-50 I would replace C-31 and C-32 as i always do on these with 105 C devices. Your resistors R-33 and R-34 seem to be OK, and there appears to be little to no board damage or solder damage < a touch up is all I would do at this point unless something comes amiss when testing these devices and the amps operation.

CR-12 and CR-13 and C-33 and C-34 all appear to be fine and their solders look OK. Again unless i find something wrong electronically I would leave these alone.

Now if you follow our advice here your out a buck at most and a few minutes reflowing some solder. I would need to test and see a issue to motivate me to do more in this area. In recap, just C-31 and C-32 need to be serviced IMO and some solder rework/touch up just for good measure.

Is that how you see it Doc ???

M-50

R33 and R34 are the hot resistors that MAY or may not need servicing. I like to reflow the solder at minimum, but these get oxided from heat so bad that the wire leads will not take solder.

So you might have to remove these and either replace them or scotch brite the lead wires to get the oxide coating off so it will take solder.

CR-12 and CR-13 are the zeners that get hot and MAY or May not need reflowing the solder. Here again its what you see when you get there. yours look pretty OK by by the pic you listed.

C-31 and C-32 are the ones that usually get baked. In your pic they appear to be good but it only cost like $1.00 to replace these and get that feel good feeling that you did the right thing. Please upgrade to 105 C rated devices if you do replace these. please elevate by 1/4 to 1/3 inch away from the board to aid in heat dispersion >

C-33 and C-34 are ceramic type caps, these rarely if ever fail. When they do you will know as they will most likely short, and burn up beyond recognition taking the traces and baord are with them as they leave for the nether regions.

on your M-50 I would replace C-31 and C-32 as i always do on these with 105 C devices. Your resistors R-33 and R-34 seem to be OK, and there appears to be little to no board damage or solder damage < a touch up is all I would do at this point unless something comes amiss when testing these devices and the amps operation.

CR-12 and CR-13 and C-33 and C-34 all appear to be fine and their solders look OK. Again unless i find something wrong electronically I would leave these alone.

Now if you follow our advice here your out a buck at most and a few minutes reflowing some solder. I would need to test and see a issue to motivate me to do more in this area. In recap, just C-31 and C-32 need to be serviced IMO and some solder rework/touch up just for good measure.

Is that how you see it Doc ???

C - on the M44, You say C-31 and C-32.. What about the resistor right above it? That should be replaced and elevated as well right?

So, M44 only summary:

1. Replace C-31 and C32

2. Replace and elevate the Orange/Orange/Red/Gold resistor above C-31/32

3. Replace the 3 caps that burn up on the right side (maybe add a 4th cap in the spare hole)

I'll probably elevate the resistors under the heat sink also as per doc's tuning link he posted...

So, M44 only summary:

1. Replace C-31 and C32

2. Replace and elevate the Orange/Orange/Red/Gold resistor above C-31/32

3. Replace the 3 caps that burn up on the right side (maybe add a 4th cap in the spare hole)

I'll probably elevate the resistors under the heat sink also as per doc's tuning link he posted...

Is this accurate?denisl wrote:C - on the M44, You say C-31 and C-32.. What about the resistor right above it? That should be replaced and elevated as well right?

So, M44 only summary:

1. Replace C-31 and C32

2. Replace and elevate the Orange/Orange/Red/Gold resistor above C-31/32

3. Replace the 3 caps that burn up on the right side (maybe add a 4th cap in the spare hole)

I'll probably elevate the resistors under the heat sink also as per doc's tuning link he posted...

denisl wrote:C - on the M44, You say C-31 and C-32.. What about the resistor right above it? That should be replaced and elevated as well right?

So, M44 only summary:

1. Replace C-31 and C32

2. Replace and elevate the Orange/Orange/Red/Gold resistor above C-31/32

3. Replace the 3 caps that burn up on the right side (maybe add a 4th cap in the spare hole)

I'll probably elevate the resistors under the heat sink also as per doc's tuning link he posted...

This is the M-50 not the M-44 the colr codes are for a M-50

So, M44 only summary: < M-50

1. Replace C-31 and C32

2. Replace and elevate the Orange/Orange/Red/Gold resistor above C-31/32

3. Replace the 3 caps that burn up on the right side (maybe add a 4th cap in the spare hole)

With that corection it all looks Ok ....Doc anymore input ? please .....C

Good catch C!! I told you I'm confused!

The M44 would be:

1. Replace C31 and C32 caps

2. Replace both tan/brown/black/gold large resistors

3. Re-solder diod next to C32

4. Replace all 4 caps which typically leak and burn

Also.. I have no idea how to identify those resistors. I assume they're special due to their size. Any help?

The M44 would be:

1. Replace C31 and C32 caps

2. Replace both tan/brown/black/gold large resistors

3. Re-solder diod next to C32

4. Replace all 4 caps which typically leak and burn

Also.. I have no idea how to identify those resistors. I assume they're special due to their size. Any help?

http://www.elexp.com/t_resist.htm

Resistor specs:

M50 - Orange/Orange/Brown/Gold

3300 Ohm +/- 5%

M44 - White/Brown/Black/Gold

91 Ohm +/- 5%

Does that look right? I'm not sure if the rating dictates the size also.. hope so.. But the M50 and M44 resistors are the same size and very different resistance specs...

Resistor specs:

M50 - Orange/Orange/Brown/Gold

3300 Ohm +/- 5%

M44 - White/Brown/Black/Gold

91 Ohm +/- 5%

Does that look right? I'm not sure if the rating dictates the size also.. hope so.. But the M50 and M44 resistors are the same size and very different resistance specs...

denisl wrote:http://www.elexp.com/t_resist.htm

Resistor specs:

M50 - Orange/Orange/Brown/Gold

3300 Ohm +/- 5% <330 ohm 1 watt ceramic metal film type 5 % tolerance but you can use 2 watt if you like>

M44 - White/Brown/Black/Gold

91 Ohm +/- 5% < 91 ohm 2 watt ceramic type but you can use sand block type also at 5 watt rating 5% tolerance>

Does that look right? I'm not sure if the rating dictates the size also.. hope so.. But the M50 and M44 resistors are the same size and very different resistance specs...

Corrected as above.....C

Can you please verify this for me:

330 ohm 1 watt ceramic metal film type 5 % tolerance

http://search.digikey.com/scripts/DkSea ... 3KW-1CT-ND

91 ohm 2 watt ceramic type but you can use sand block type also at 5 watt rating 5% tolerance

http://search.digikey.com/scripts/DkSea ... 91W-2CT-ND

I couldn't find 91ohm in ceramic but it was listed in metal type. I also couldn't find sand type.

I'm almost there... thanks again..

330 ohm 1 watt ceramic metal film type 5 % tolerance

http://search.digikey.com/scripts/DkSea ... 3KW-1CT-ND

91 ohm 2 watt ceramic type but you can use sand block type also at 5 watt rating 5% tolerance

http://search.digikey.com/scripts/DkSea ... 91W-2CT-ND

I couldn't find 91ohm in ceramic but it was listed in metal type. I also couldn't find sand type.

I'm almost there... thanks again..

denisl wrote:Thanks..

Do you see any issue using the 5600uf caps Doc used in the M100 in the link he provided? All the 6800's I found are 35.5mm high which is too big by half mm. The 5600's are 31.5mm high which sould give me the clearance to add a fourth to the M50.

5600 ufd is Ok...Anything larger is better here as long as its not too Tall to fit the case....C

Just put my order in with digikey.. Hope I got all the right stuff!!!!

Thank you C and Doc for all you help. I couldn't have gone this far without you guys.

Here's what I ordered....

QTY-- P/N--------------------DESC-----------------------------------------$USD

10----493-1543-ND--------CAP 5600UF 16V ELECT HE RADIAL----$10.44

10----493-1850-ND--------CAP 10UF 35V ELECT PW RADIAL-------$1.51

5------PPC330CCT-ND-----RES 330 OHM 1W 5% MF FUSIBLE-----$2.45

5------PPC91W-2CT-ND----RES 91 OHM METAL FILM 2W 5%------$3.02

Thank you C and Doc for all you help. I couldn't have gone this far without you guys.

Here's what I ordered....

QTY-- P/N--------------------DESC-----------------------------------------$USD

10----493-1543-ND--------CAP 5600UF 16V ELECT HE RADIAL----$10.44

10----493-1850-ND--------CAP 10UF 35V ELECT PW RADIAL-------$1.51

5------PPC330CCT-ND-----RES 330 OHM 1W 5% MF FUSIBLE-----$2.45

5------PPC91W-2CT-ND----RES 91 OHM METAL FILM 2W 5%------$3.02

in the mean time get your hands on the following:

some q tips, wooden kind are best

some lint free wipes, similar to tissue

a exacto knife to cut the old RTV holding the caps so the can be pulled one by one and not together.

Some solder wick with flux medium width

some acetone or flux remover either or does not matter

some RTV in a small tube like chalking is sold in, I prefer clear instead of colored RTV

Some good solder, you can't find the old solder they used on these anymore as its outlawed because it has lead in it, so you will have to get some of the alloy stuff thats out.

You will need these things along with a good variable temp soldering iron.

Best of luck, and please practice patients and care when removing old caps, they can pull out the little vias that were made in the board that connect the front to the back side of the board.

If you do this you must hard wire the board back together before replacing the caps in most cases...

Patience is a must, and do not force anything.....C

some q tips, wooden kind are best

some lint free wipes, similar to tissue

a exacto knife to cut the old RTV holding the caps so the can be pulled one by one and not together.

Some solder wick with flux medium width

some acetone or flux remover either or does not matter

some RTV in a small tube like chalking is sold in, I prefer clear instead of colored RTV

Some good solder, you can't find the old solder they used on these anymore as its outlawed because it has lead in it, so you will have to get some of the alloy stuff thats out.

You will need these things along with a good variable temp soldering iron.

Best of luck, and please practice patients and care when removing old caps, they can pull out the little vias that were made in the board that connect the front to the back side of the board.

If you do this you must hard wire the board back together before replacing the caps in most cases...

Patience is a must, and do not force anything.....C

C - I have everything on your list except wick which I'll get.

One more quick question...

This is your quote from another thread:

This is the thread (outlaw 1845):

http://phoenixphorum.com/which-capacito ... t4125.html

Just making sure my eyes read 10uf correctly otherwise I'll order up some 100uf's 25vdc.

I also found the 6800uf 35mm caps on ebay for 30 bucks - is it worth getting over the 5600's?

http://cgi.ebay.com/10pcs-Nich-16V-6800 ... dZViewItem

One more quick question...

This is your quote from another thread:

Those caps on my amps I read to be 10uf 35vdc, not 100uf 25vdc. Are we talking the same caps?You will find these near the big resistors located in the power supply section, They are the 100 ufd caps rated at 25 volts. If you check these while the amp is running you will find them be rather HOT to the touch.

This is the thread (outlaw 1845):

http://phoenixphorum.com/which-capacito ... t4125.html

Just making sure my eyes read 10uf correctly otherwise I'll order up some 100uf's 25vdc.

I also found the 6800uf 35mm caps on ebay for 30 bucks - is it worth getting over the 5600's?

http://cgi.ebay.com/10pcs-Nich-16V-6800 ... dZViewItem

10 ufd @ 35 volts is the correct part for a M-44

100UFD @ 25 volts is the correct part for a M-50

The outlaw has a M-50 section and a M-100 section your M-50 is in there but your M-44 in not as it is a M-100 in the Outlaw LE

As for the heat thing I mentioned, you will also notice the large resistors also get very hot. Heat will transfer through the traces and the board, and the air to surrounding components. These caps in all these amps get real hot. weather it be ripple current related or direct connection to the zeners and large drop resistors its still high heat, hence my intent to replace everyone of these I see with new higher rated devices. Its just good practice for me because over the years I trained myself to go the extra to avoid the embarrassment of a rework warranty issue.

As for the E-bay caps I have found some great deals on e-bay from time to time, as for these specific caps I honestly can not say. They seem to have OK spec's but unless I have then to test in my setups < Bench tools> I can't in honesty say they will work all that well. If a real part number was available and a date code I would be more inclined to give a yes or no answer. Old caps are as bad as old used caps IMO, they have a shelf life and a use lifespan in their ratings for a reason

The risks involved are a very short life span before you see similar failure of the device. I.E. a early device failure will put you back in the amp reworking your efforts. A good question is how much is your time worth ?

Thats what I ask myself before I do something I do not have 100% faith and trust in......C

100UFD @ 25 volts is the correct part for a M-50

The outlaw has a M-50 section and a M-100 section your M-50 is in there but your M-44 in not as it is a M-100 in the Outlaw LE

As for the heat thing I mentioned, you will also notice the large resistors also get very hot. Heat will transfer through the traces and the board, and the air to surrounding components. These caps in all these amps get real hot. weather it be ripple current related or direct connection to the zeners and large drop resistors its still high heat, hence my intent to replace everyone of these I see with new higher rated devices. Its just good practice for me because over the years I trained myself to go the extra to avoid the embarrassment of a rework warranty issue.

As for the E-bay caps I have found some great deals on e-bay from time to time, as for these specific caps I honestly can not say. They seem to have OK spec's but unless I have then to test in my setups < Bench tools> I can't in honesty say they will work all that well. If a real part number was available and a date code I would be more inclined to give a yes or no answer. Old caps are as bad as old used caps IMO, they have a shelf life and a use lifespan in their ratings for a reason

The risks involved are a very short life span before you see similar failure of the device. I.E. a early device failure will put you back in the amp reworking your efforts. A good question is how much is your time worth ?

Thats what I ask myself before I do something I do not have 100% faith and trust in......C